Stay Precision machining Field , Whether or not Aluminum processing , Still Machining stainless steel, All need horizontal lathe 。 Today , Let's learn about the basic structure of its main shaft system 。

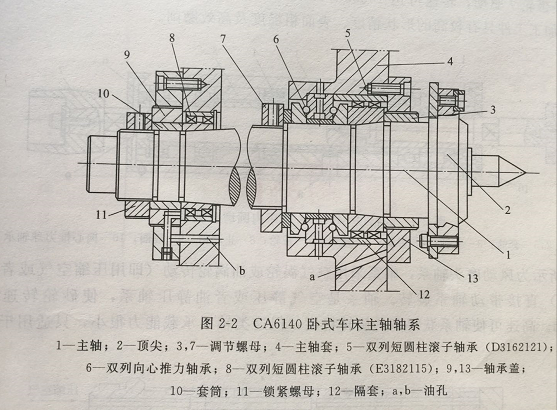

Chart 2-2 Shown as CA6140 Spindle system of horizontal lathe , Before spindle 、 Double row cylindrical roller bearings are installed at the rear support 5 And 8, Intermediate support ( Chart Not drawn yet ) It is also equipped with single row radial short cylindrical roller bearing E32216 For radial force 。 Installed at the front support 60° Angular contact double row radial thrust bearing 6 For bearing left 、 Axial force in right two directions 。

The preload of the front bearing consists of 3、13 And 7 Adjust , Rear bearing components 10、9 Adjust , By component 11 Locking 。 The spindle is a hollow stepped shaft , The inner hole can supply long bar And Pneumatic 、 The transmission rod of hydraulic clamping drive device passes through 。 The front end is precision Morse taper hole , For mounting the center or spindle 、 Chuck 、 Dial, etc. 。

Stay Precision machining In the process of , The spindle speed range is 10-1400r/min。 The shafting is supported in three places , Increased rigidity And Vibration resistance , The use of cylindrical roller shafting improves the bearing capacity 。 The rotation accuracy of shafting depends on the accuracy of bearing And Preload Adjust 。

This article Tags : Precision machining , Aluminum processing