Precision machining Better equipment , It plays an important role in time efficiency and quality in the effective forming process of pipe ends 。 To achieve this goal , Whether you are using seamless steel pipe with longitudinal weld or tube , Whether seamless pipe or pipe with longitudinal weld , Can guarantee and add more equipment , To reduce processing time and obtain better surface effect

Electronic preselection saves time and manpower

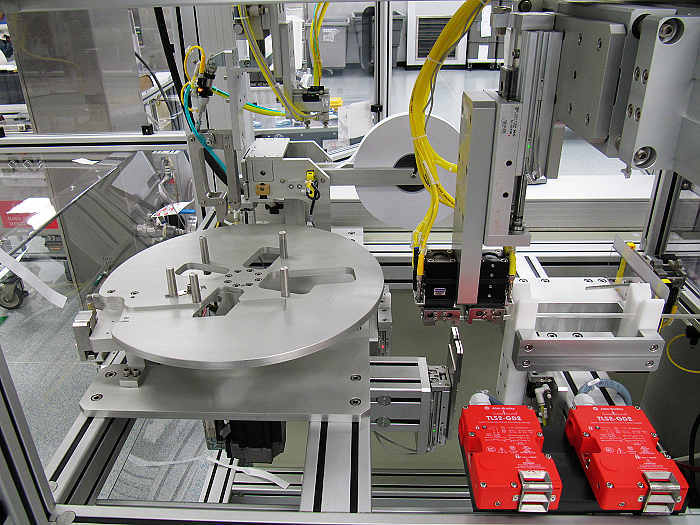

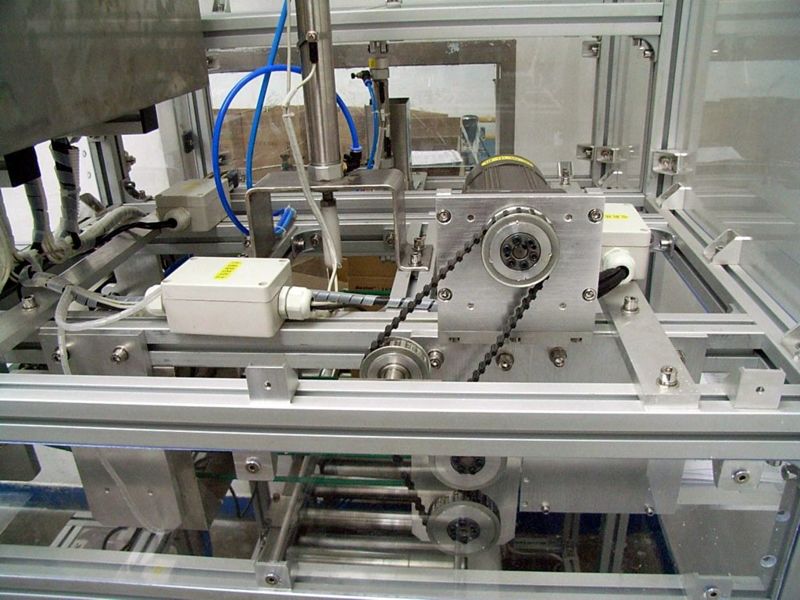

To form a tube by rolling or rotating a fluid solution 。 For example , Rolling technology of bead rolling mill 。 This allows various forming results to be achieved at the end of the tube , And has a high precision reduction over a long distance , And it can form thread with rolling system 。

On the other hand , The rotating process can make multiple flares at the end of the tube , In diameter 20° And 90° Angle or profile between , For example Spherical 。

“ In the past , The stop must be set manually for both machines And Trip , In order to obtain good geometry on the surface 。 The latest generation of machines , Benefits of the latest tube forming machine 。 Now , The device includes a range of optional flare geometry , Can be selected electronically 。 Location of stops and all Trip And The operation is controlled by servo motor , And can be retrieved through the touchpad 。

Processed materials And The type of molding required is critical to the exact time of the process 。 When the size of the tube and the required process parameters can be retrieved , The machine completes the process almost independently 。 In each case , The clamping length of the production process is 1 Times to 1.5 Between times 。 Such , The operator always has the option of forming after the bending step 。 Through this solution , Complex forming geometry can be produced more economically in a single forming step and flared using a polished sealing surface 。

This article Tags : Processing equipment , Processing technology