-

-

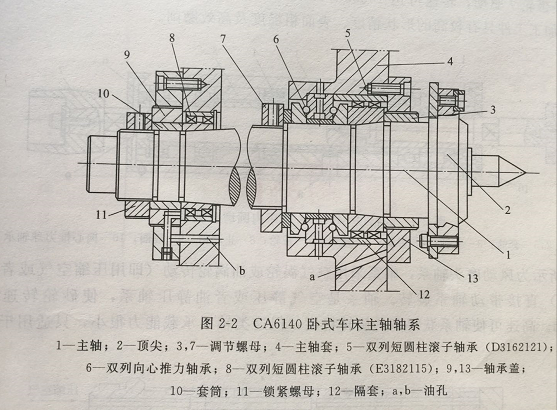

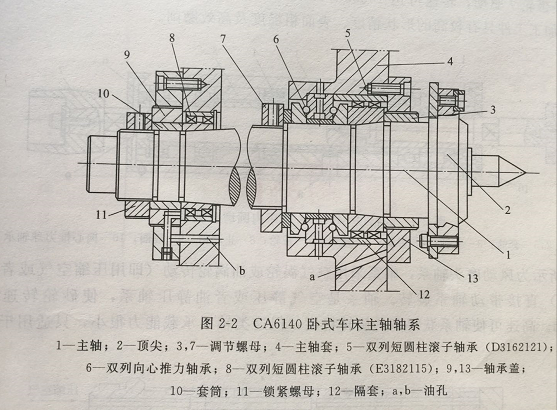

Stay Precision machining Field , Whether it's aluminum processing , Stainless steel processing , All need horizontal lathe 。 Today , Let's learn about the basic structure of its main shaft system 。 Chart 2-2 Shown as CA6140 Spindle system of horizontal lathe , Before spindle ...

-

-

1、 Rail wound If the machine tool for parts processing is used for a long time , There is a change in the level of foundation and bed , Make the local unit area load of guide rail too large , The level adjustment of the bed guide rail should be carried out regularly , Or repair the precision of guide rail ; In case of long-term processing of short workpiece or bearing ...

-

-

Customized service center for parts processing , All lubricating parts of the machine tool must be lubricated according to the Chart Regular refueling , The injected lubricating oil must be clean 。 The lubricating part shall be oiled once a week , Find out the law of fuel consumption , In case of any decrease in oil supply, the maintenance personnel shall be informed in time for maintenance 。 Mechanical zero ...

-

-

Stay Precision machining Enterprise , Maintenance of CNC machine tools , Can improve Precision machining Efficiency and accuracy of , Carry out spot check as required during daily use and maintenance , At the same time, make maintenance records 。 1、 Choose the right environment CNC machine ...

-

-

1、 Rigidity of shafting in precision machining factory Mainly determined by the structure of the shafting , Especially the rigidity of the medium between the main shaft and the main shaft sleeve 。 Increasing the spindle diameter increases rigidity , But the structural size of the shafting is increased 。 High precision parts customization , If the spindle is designed as a ladder ...

cache

Processed in 0.029660 Second.